Unlocking the Power of Adventus Lignin 360 Sustainable Lignin Innovator

Adventus Lignin 360 is making waves in the world of sustainable materials by leveraging lignin—nature’s second most abundant biopolymer as a renewable bio-binder for green asphalt, adhesives, and high-performance composites. As the world pivots away from petroleum-based materials, Adventus aims to redefine construction and materials engineering through its proprietary Lignin 360 platform.

By converting lignin waste from biomass refineries into durable, cost-efficient alternatives, the company targets a wide range of industries—especially road paving—starting in 2027 with green asphalt trials.

With potential applications extending to carbon fibers, bio-resins, plastics, and adhesives, Adventus positions Lignin 360 at the intersection of environmental innovation and circular economy values. This article explores the technology, real-world benefits, sustainability credentials, and future potential of Adventus Lignin 360.

1. What Is Adventus Lignin 360?

Adventus Lignin 360 is a branded platform centered on high-value uses of lignin extracted from biomass and pulp and paper byproducts. It transforms lignin into bio-adhesives, asphalt extenders, renewable fuels, and engineered road materials.

The technology builds on lignin’s natural binding capacity to reduce reliance on fossil-based asphalt and resin products, offering greener alternatives with lower carbon footprints.

2. Why Lignin Matters Scientifically and Economically

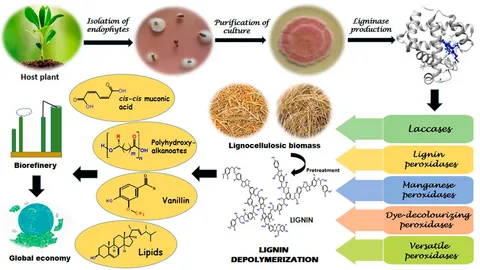

Lignin is an aromatic polymer present in plant cell walls, naturally binding cellulose fibers and accounting for ~20–30% of biomass. Historically considered a low-value fuel, modern science now reveals its versatility.

Activated carbons, composite additives, adhesives, and even rare earth adsorption materials. The global lignin products market is expanding fast, driven by sustainability trends across construction, chemicals, and energy sectors.

3. Adventus’s Green Asphalt Initiative

Adventus Lignin 360 plans to launch green asphalt made from Lignin 360 starting in 2027. Initial trials in Europe using patented lignin mixtures have demonstrated improved road durability across multiple climates.

The company projects capturing a share of the $30B U.S. paving market by offering asphalt alternatives that perform better, cost less, and reduce greenhouse-gas emissions versus conventional petroleum binders.

4. Broader Applications and Technical Insights

Beyond paving, Lignin 360 is enabling high-performance bio-plastics, carbon fibers, and sustainable adhesives. Advanced Lignin Partners see possibilities in automotive components, sports equipment, and energy storage materials derived from lignin‐based polymers.(Waste360) Research continues to evolve, exploring 3D‑printing materials, lignin chemistry, and composite mechanics.

5. Environmental and Circular-Economy Credentials

Lignin valorization through Adventus Lignin 360 platform aligns with global sustainability goals. By converting lignin waste into valuable products, it closes biomass loops and lowers reliance on virgin fossil resources.

Lignin-based admixtures are also being explored in cement composites to reduce emissions and improve material properties.The platform addresses both industry demand and environmental pressure toward greener industrial processes.

6. Challenges & Future Outlook

Adoption challenges include industrial scale-up, feedstock standardization, and regulatory validation. Lignin’s structural heterogeneity complicates consistent processing and performance. However, partnerships and pilot projects.

Like those launched by Adventus in the road paving sector—are key steps toward market readiness. Their ongoing innovation suggests the platform may soon shift from pilot to mainstream across multiple industries.

Read More: Follow us here at my Homapge NoodleMagazine

Conclusion

Adventus Lignin 360 exemplifies the shift toward circular, nature-derived materials with genuine industry potential. Positioned to disrupt traditional asphalt, adhesive, and composite markets.

The platform transforms lignin waste historically considered a low-value byproduct—into high-performance, eco-friendly alternatives. With green asphalt trials commencing in 2027 and expanding into bio-plastics and carbon fiber, Adventus bridges innovation with scale.

FAQs

1. What is Adventus Lignin 360 used for?

It’s a platform converting biomass lignin into sustainable materials like green asphalt, bio‑adhesives, plastics, and carbon fiber alternatives.

2. When will Lignin 360 asphalt be commercially available?

Commercial road trials begin in 2027, with planned entry into the U.S. market shortly thereafter.

3. How does lignin-based asphalt compare to petroleum asphalt?

Studies show Lignin 360 asphalt can be more durable, lower cost, and significantly reduce CO₂ emissions in production and lifecycle.

4. Can lignin really replace plastics or adhesives?

Yes. Research and pilot projects demonstrate lignin-derived polymers and composites performing comparably to petroleum-based versions in adhesives, bio-plastics, and carbon materials.

5. Why is lignin considered sustainable?

Lignin is a renewable byproduct of biomass refining, non-toxic, biodegradable, and helps close circular economy loops by repurposing waste for high-value materials.